3 min read

Product packaging software – what is it?

Are you an emerging graphic packaging designer seeking the best software for crafting packaging designs? Or perhaps a brand manager overseeing...

4 min read

Joanna Gränström

:

2024-07-04 03:04

Packaging project management – ever heard of it? It’s the behind-the-scenes work in a packaging implementation and design project that size wise goes beyond everyday retail packaging management. You manage a bunch of designs, even more artworks, with constantly changing content created and reviewed by lots of stakeholders, all while facing tight deadlines that can’t budge without breaking the bank.

As a packaging PM, handling retail packaging management at Collabra, I tend to think “in this upcoming project I probably won’t need half of my meticulous preparations, I’m just being nitpicking”. But I’ve yet to experience a project where they haven’t saved all our behinds at least once. So, as I pass on my experience to new colleagues, I’d like to share these seven essentials with you too:

Table of Contents

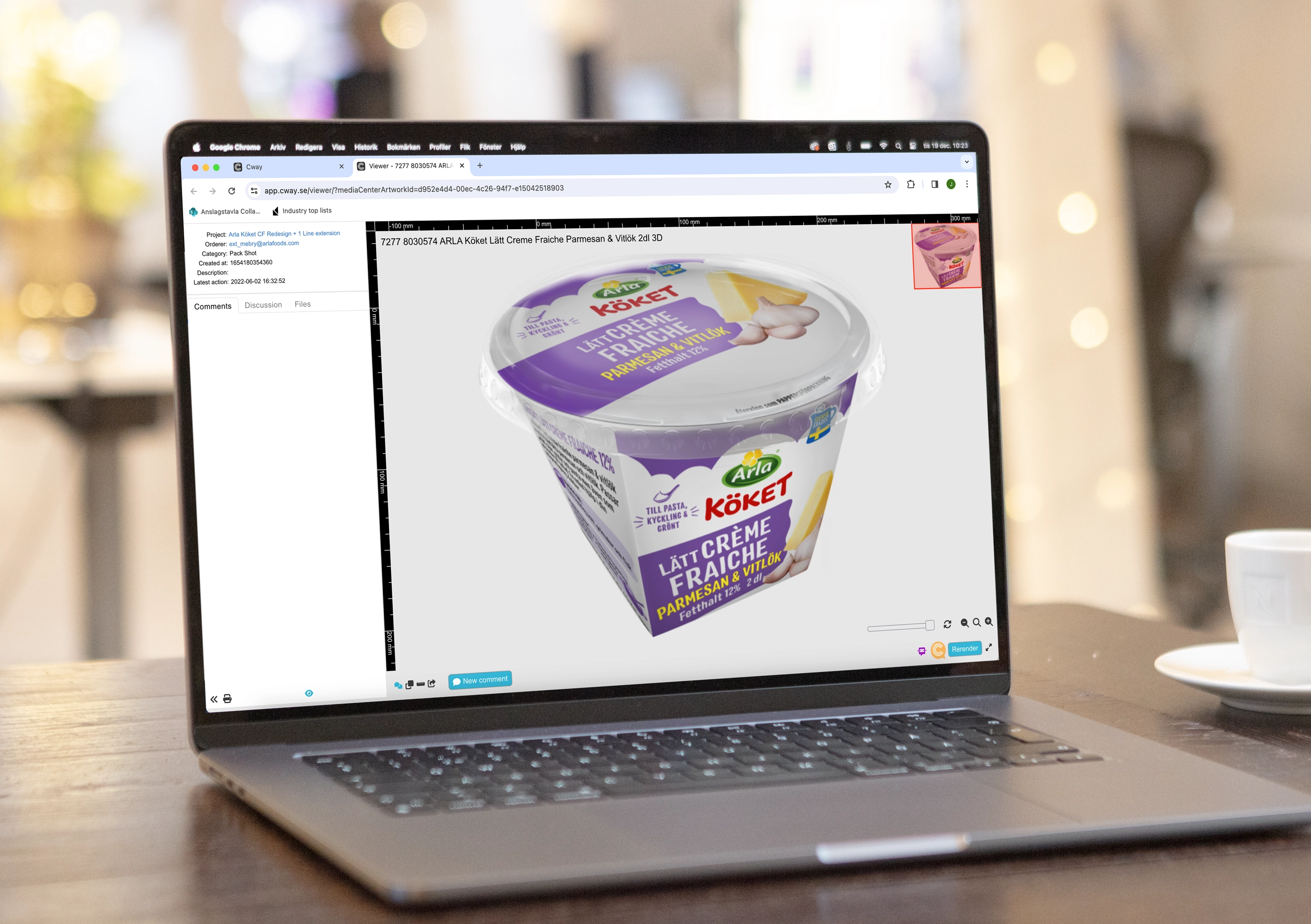

First and foremost, give your project a true game-changer by using a software for artwork review and management. This software automates tasks and allows all team members to work together in one place. Cway, in particular, offers clear packaging project management, user-friendly features that even temporary team members can use with next to no training, and it takes care of recurring tasks like notifications and progress reports that are usually handled through confusing and time-consuming emails. It saves loads of time and effort, and reduces plenty of risk.

The better we understand the project and its assortment, the more errors can be avoided. Some clients rush to print the bestseller artwork to get the ball rolling, making management temporarily happy, but it forces either inconsistent design solutions for the odd packs, or could require creating new designs for the entire lineup when the design agency no longer has the time. So - handling odd packaging early ensures a more solid project plan and protects your brand’s intended image, which you’ve invested heavily in achieving.

Neglecting packaging content management, such as ignoring to approve it beforehand, or creating lists with repeatedly copy-pasted content, can seriously disrupt project. Imagine the chaos when a lenghty translation, riddled with overlooked errors, ends up on multiple artworks. We’ve had to review artworks with over 90 comments each, while launching 30 artworks a week and preparing the same amount for the review process a week ahead. It was a handful. To prevent this issue, we consistently collaborate with our clients in and between projects to help them enhance their packaging content management practices. Nobody wants neither to review nor correct that amount of artworks, as it can delay any project massively.

We always address those seemingly insignificant issues that are seemingly insignificant, because they’ll become big headaches later. In one retail packaging management project, our anti-risk group identified a potential risk with two different sets of addresses and country of origin that would impact the design in various ways on different packs. It took a while to resolve it but proved invaluable in keeping the overall project timeline intact. Dealing with a known risk is more manageable than an unexpected one, so we ask around the organization about what COULD happen. We map the unknowns so that, while we may not know the exact changes, we understand their nature and likelihood. Then we keep a close eye on issue progress and make room for potential changes in our project timeline.

Extensive packaging projects seldom allow for a pause in an organization’s regular tasks; instead, they’re layered on top of everyday assignments, often causing stress and bottlenecks. That’s why we strategically plan our projects with our customers’ other commitments in mind. To create ample space for everyday tasks, we schedule online proofing on specific dates. This approach allows clients to dedicate more attention to proofing on those designated days, making the process faster and more reliable. It also gives them the flexibility to schedule meetings and tackle other work on the remaining days.

Changes will come, you can count on that. Typically, these changes impact not only work in progress but also previously delivered graphics, potentially creating chaos in the project. Instead of permitting changes to delay the project, we proactively create flexibility in our planning to accommodate them. By maintaining a slightly faster overall project pace, we make room for ‘change weeks’ to pause the project and address any necessary changes. The best outcome: finish early. The worst: revoke and reimplement, but at least we have time to do it.

As changes come up, there will be decisions to make. Decision makers tend to move on when it’s time to implement designs, making them hard to reach. An effective solution is to plan brief decision meetings regularly throughout the project. Before the meeting, we provide a straightforward description of the problem and possible solutions to enable quick decisions. As the project progresses, you’ll need fewer of these meetings, giving decision makers unplanned extra time for other tasks.

Incorporate these preps into your packaging project management strategy, and I promise that you’ll be far better equipped to tackle complex projects successfully. Or call us and we’ll do it for you.

Packaging project management involves overseeing the design, development, and implementation of packaging for products. It includes tasks such as design coordination, content management, quality control, and timeline management to ensure the successful creation and delivery of packaging materials. The goal is to efficiently produce packaging that aligns with the brand's image, meets regulatory requirements, and enhances product presentation while staying within budget and schedule constraints.

Retail packaging management refers to the systematic and strategic handling of all aspects related to packaging within a retail environment. This includes the design, production, distribution, and presentation of packaging for products sold in retail stores. The primary goal is to create packaging that not only protects and promotes the products but also aligns with the brand's identity and appeals to the target audience. Retail packaging management aims to optimize packaging processes, reduce costs, improve sustainability, and enhance the overall shopping experience for customers while ensuring compliance with industry standards and regulations.

Packaging content management involves creating, organizing, and maintaining text, images, and legal information on product packaging to ensure compliance, brand consistency, and consumer engagement.

A packaging project management system is a software or framework designed to oversee and streamline the various processes involved in creating and managing packaging for products. It helps coordinate tasks, resources, and timelines to ensure efficient and effective packaging development and production. Key features of such a system typically include task assignment, workflow automation, version control, collaboration tools, and reporting capabilities. These systems are valuable for ensuring packaging projects are completed on time, within budget, and meet quality and regulatory requirements.

%20(1)%20(1).jpg)

3 min read

Are you an emerging graphic packaging designer seeking the best software for crafting packaging designs? Or perhaps a brand manager overseeing...

%20(1).jpg)

Packaging artwork management is the process of overseeing a brand owner’s packaging designs over time. Think of it as the technical cousin of...

%20(1).jpg)

4 min read

Brand owners are well-versed in the value of their products and the critical role of packaging in the marketplace. Packaging serves as the initial...