1 min read

Is it time for a packaging redesign?

Packaging redesign is the process of updating and improving the visual and functional aspects of a product's packaging to better align with current...

3 min read

Ekaterina Skalatskaia

:

2024-08-30 09:00

Ekaterina Skalatskaia

:

2024-08-30 09:00

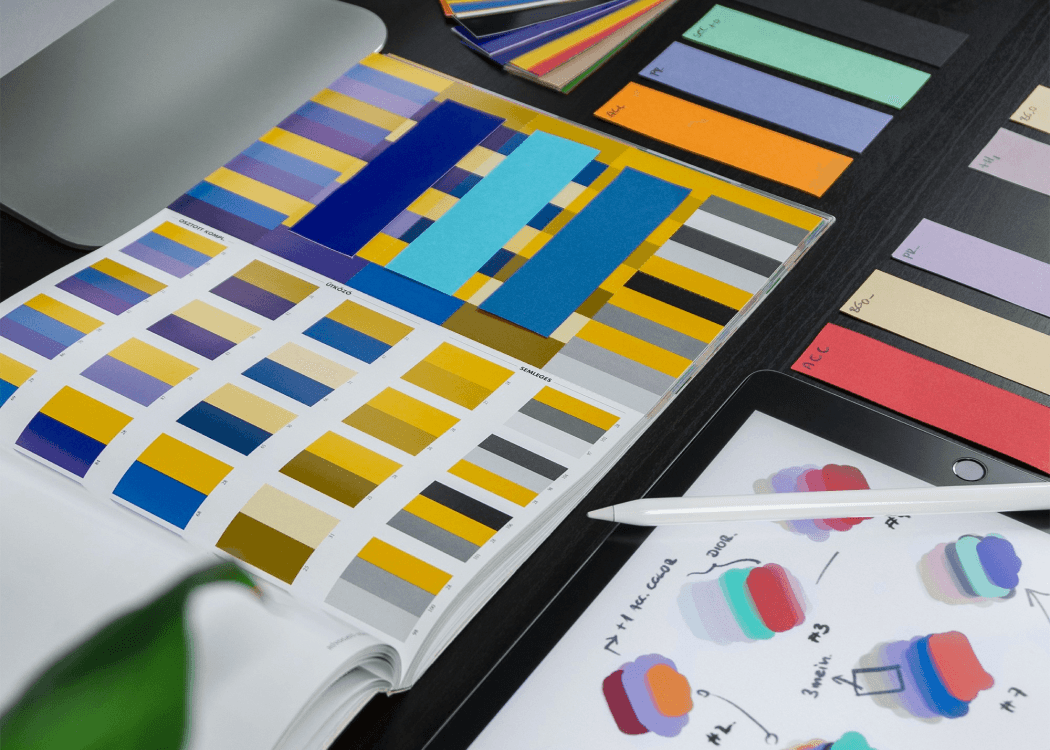

Design considerations are paramount in the packaging industry, serving as a cornerstone for brand identity and consumer perception. Brands invest significant resources into crafting designs that not only reflect their values and messaging but also resonate with their target audience. However, achieving this balance of consistency and adaptability poses a considerable challenge.

For instance, a brand may need to maintain a cohesive visual identity across multiple product lines while accommodating variations in size, shape, and packaging material. This requires designers to develop versatile designs that can be scaled and modified without compromising brand integrity.

Graphics must maintain their clarity and detail at varying sizes and resolutions, from large packaging to tiny labels. This challenge requires high-resolution designs that can be scaled without loss of quality. Designers must anticipate the different applications of each graphic element to ensure that resolution and scaling adjustments do not compromise the visual integrity of the brand or the readability of important information.

Proper alignment and registration are critical in multi-layered prints and when applying graphics across various packaging forms. Misalignment can result in blurred or double images, negatively impacting the product's appearance on the shelf. Precision in the printing process and rigorous quality control measures are essential to ensure that all layers of the graphic align correctly, delivering a sharp and cohesive final product.

The choice of finishing techniques and materials significantly affects the aesthetic and functional qualities of product packaging. Finishes such as matte, gloss, embossing, or special coatings can enhance visual appeal and tactile experience, but they require careful consideration of the material properties and printing capabilities. Additionally, the durability of materials and finishes must be aligned with the product's intended use and shelf life.

Print limitations pose a multifaceted challenge for packaging design teams, as they navigate the complexities of translating digital concepts into tangible, printed materials. Unlike digital displays, which offer precise control over color, texture, and resolution, print outcomes are influenced by a multitude of factors, including substrate, ink, printing method, and environmental conditions. These variables can lead to unexpected discrepancies between the intended design and the final printed product, necessitating careful planning and proactive problem-solving. Additionally, designers must account for factors such as dot gain, trapping, and ink bleed, which can affect the clarity and fidelity of printed graphics.

To reduce the risks associated with print limitations, design teams can leverage advanced prepress tools and software solutions that simulate print outcomes and identify potential issues before production. By conducting thorough print tests and collaborating closely with print vendors, designers can optimize design files for specific printing processes and substrates, minimizing the likelihood of errors and ensuring consistent quality across print runs.

Moreover, embracing innovative printing techniques such as metallic inks, embossing, and varnishes can add visual interest and dimensionality to packaging designs, enhancing shelf appeal and brand differentiation. By staying abreast of emerging trends and technologies in the printing industry, designers can leverage these capabilities to create memorable and impactful packaging experiences for consumers.

Effective communication and collaboration serve as linchpins in the successful creation of product graphics, requiring harmonious interaction among various stakeholders involved in the process. From designers and brand managers to printers and material suppliers, each participant plays a crucial role in bringing the vision to life.

Clear and timely communication is essential to ensure that design intentions are accurately interpreted and executed. Miscommunication or misunderstandings can lead to costly errors and delays in production.

Collaboration tools such as Cway offer invaluable support in streamlining workflow and artwork management. Artwork management software facilitate real-time collaboration, allowing stakeholders to share feedback, track project progress, and make informed decisions throughout the design process. By centralizing communication and project documentation, these tools help in reducing communication gaps and ensuring that everyone is aligned towards the common goal.

Addressing these challenges effectively requires a combination of expert knowledge in print and design, alongside powerful IT software like Cway® that streamline the entire process. Such soft store and organize all relevant data, automate workflow, ensure design and content accuracy, and facilitate easy updates and adaptations. This approach not only mitigates the risks associated with product graphics but also enhances efficiency, allowing brands to maintain a competitive edge.

In essence, the creation of product and package graphics necessitates a meticulous strategy encompassing content management, design precision, print optimization, and streamlined processes. By capitalizing on expertise and cutting-edge technologies, these challenges can be reframed as opportunities for brands to distinguish themselves and thrive in the market.

1 min read

Packaging redesign is the process of updating and improving the visual and functional aspects of a product's packaging to better align with current...

Imagine this: your product is ready to hit the shelves, but there's a problem—the packaging graphics are wrong. Maybe the colors are off, the design...

Print coverage in packaging design refers to the percentage of the surface area of packaging that is covered by ink or printed elements (like...